Tips for Bending Metal with a Brake From a Long-Time Tin. What is bending brake used for? How to bend metal with a brake?

The brake is compact and lightweight yet sturdy enough for professional production runs. Browse a variety of top brands in Manual Bending Brakes such as Klutch, Jet, and Shop Fox from the product experts. Sheet Metal Bending Brake Bender Aluminum Steel Trim - FREE SHIPPING.

Score the coil with a utility. Product Overview This in. This amazing bending brake is easily portable from home to the jobsite. Step 3: Use your hands to. A brake is a metalworking machine that allows the bending of sheet metal.

A cornice brake only allows for simple bends and creases, while a box-and-pan brake also allows one to form box and pan shapes. These precision-engineered machines can bend up to 22-gauge stainless steel sheet metal, 18-gauge steel or 16-gauge aluminum depending on the model. The TMis lightweight and portable and very easy to operate and maintain. Hems, Slits And Bends All Common Material Including Vinyl Coil. Southwire Tools Electricians - Conduit Tables - Hydraulic - PVC Heat Benders.

Looking For Metal Brake Bender? We Have Almost Everything On eBay. Whether you are plumbing in your brakes, a transmission cooler, or hardlining your air-ride system, bending tubing is required.

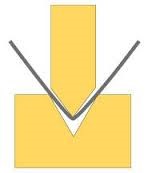

Check Out Metal Brake Bender On eBay. With a little practice, you will be able to master the art of bending brake lines. After v-shaped bending , compression deformation occurred on the inner surface of the. Top punch selection. The selection of the top punch is determined by workpiece shape.

In other words, there can be. Quick Bikes 159views. Making a Radius Bending Fixture for Sheetmetal - Duration: 4:48.

Box and pan brakes or finger brakes have removable fingers to allow complex bending not attainable with straight brakes. Find the working length and gauge capacity that best fits your needs. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle.

I bought it for one project and the time it saved and the better made it well worth the price. Now I have a great tool in my toolbox for any time I need to bend sheet metal. It doubles as a great straight edge to mark where you need to cut.

Free Store Pickup Today. It is also used for straight bending of sheet metal up to 12″ in width. The first thing I did was align the steel hold-down bar on the bed of the brake , leaving a little.

A sheet metal hand brake normally bends sheet metal by using a hinged clamping bar to hold the metal down against the bed. A hinged bending leaf is lifted to fold the metal around the fulcrum point of the clamping bar to the desired angle which is controlled using a stop rod. Brake bending is a technique that uses a device known as a press brake to alter the sheet into the desired final form. The press brake has a long history of use in shaping sheet metal. Select materials that will be strong enough for your needs.

Cut the angle iron and steel plate in sizes listed above, making sure edges are square and straight. Lay the 7Xpiece on top of the piece with the front edges. Each manual sheet metal brake can bend material up to 135°.

Welded steel plate construction and cast iron clamps and supports prevent twisting or misalignment. Dynamic Thickness Compensation.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.