What does floating concrete mean? How do you make concrete float? The bull float should have rounded ends, not flat or straight ends.

A floating concrete structure is a solid body made of reinforced concrete and an inner chain of chambers filled with a lightweight impermeable material , typically polystyrene. Praeger and built by the New York City Marine and Aviation Department, this pier has hidden below it a historically unique concrete structure that floats on water. That is to say, Pier does not stand on a conventional pile field.

Options for Front Walkway and Steps. You can create steps using a variety of materials: Brick or Pavers - easier to DIY. Floating slabs are concrete slabs that are laying over the ground , without any kind of anchoring , as if it simply sits on it and floats. Floating slab, as the name tells it resembles a plate that is simply laid over water, with no kind of connection between them. QLT by Marshalltown 9-in x 4-in Molded Black Rubber Concrete Float.

Concrete wall tiles, concrete 3d tiles, contemporary furniture, modern furniture, tiles for feature walls and accent walls. Our concrete tiles can also be used as flooring tiles. Construction of Floating Slab A: Site Excavation for Floating Slab Construction. The initial stage of floating slab construction is to clear the land.

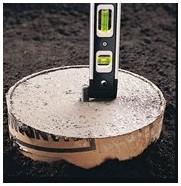

C: Reinforcement for Slabs. The slab mold is placed for casting procedure. To strengthen the slab, the. A concrete float is a tool used to finish a concrete surface by making it smooth.

A float is used after the surface has been made level using a screed. In addition to removing surface imperfections, floating will compact the concrete as preparation for further steps. A float can be a small hand tool, a larger bull float with a long handle, or a power trowel (also called a power float) with an engine. Use a bull float for areas too large to reach with a darby or hand float, though it may produce a wavier surface. Floating concrete slabs provide solid foundations for structures as sheds, garages, home additions, and even manufactured homes.

Kraft Tool CC8Walking Magnesium Concrete Float x 3. Get it as soon as We Jul 1. FREE Shipping by Amazon. Because of its low density and moderate range of compressive strength, it can be used in non-structural applications as of now. When Do You Use the Bull Float When Pouring Concrete ? Prior to finishing, concrete is poured into forms and compacte or consolidated.

Initial finishing begins with. A bull float looks like a flat board attached to a long handle. Pulling the flat surface of the bull float. There are two leading types of concrete floating dock systems: waler connected and bolted. The name refers to the method used to connect individual modules together.

Evaluate the space where you plan to install the floating flooring. Before you go about laying down your floating. If your subfloor is concrete , cover it with a wood or engineered wood subfloor first. Prepare your space.

Laying down your floating.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.