Can You stain pressure-treated wood? When do you stain pressure treated wood? Stain the pressure treated wood using a paint pad applicator , which is easier than brushing a large deck or structure by. What is pressure treated wood used for? Use a paintbrush to stain between cracks and problem areas.

Usually no more than one coat is needed. Expect the butted ends of lumber to accept more stain. Can I Stain Pressure Treated Wood? This lumber can be stained as soon as the deck is built. Ordinary pressure-treated lumber from.

A semi-transparent exterior wood stain helps maintain the fresh appearance of a pressure-treated wood deck and provides added protection to the wood fibers. Many manufacturers recommend waiting for three to six months before applying a stain or sealant to new decking, but other experts advise staining exposed lumber immediately. You can typically stain regular wood immediately. With pressure treated lumber, you might be able to stain it immediately or you might have to wait a bit.

Staining pressure treated wood helps in preserving its color, appearance, and texture. In order to stain pressure treated lumber, you can use an oil-based , semi-transparent , or solid color finish. The steps for this process have been enlisted here. Wood is no doubt one of the most versatile materials for construction purposes. Sealing , Painting and Staining Pressure Treated Wood A project's not really done until it's finished.

If the water soaks into the woo then it’s dry and ready for stain or paint. You probably know that wood swells when it gets wet and shrinks when it dries. Pressure treated wood is designed to repel moisture and insect damage in outdoor areas.

However, new pressure treated wood usually has a high moisture content, which can derail your staining. Trust Lumber Liquidators to Help You Bring Your Beautiful New Floors to Life. Give All Your Projects The Perfect Finish With Varathane Classic Wood Stain. Pour some of the stain into a container and stir the stain well. Using a brush, apply the stain to the rails and spindles.

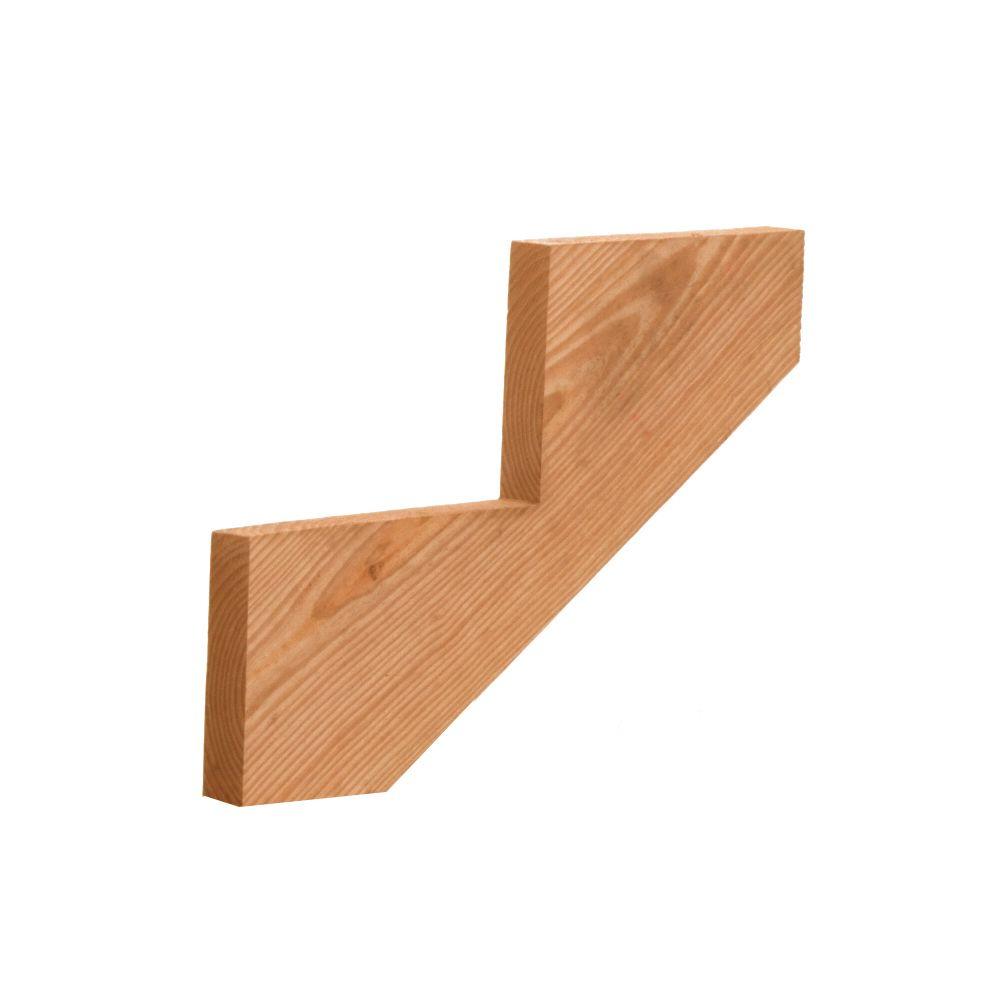

The Stain Stick has an attached stain. How to Prep New Pressure Treated Wood for Staining 1. Ask for the oldest pressure treated wood when purchasing it from the lumber yard or home improvement store. Put on goggles and a dust mask. Sand all sides of the lumber with medium-grit sandpaper to roughen the surface.

Mix a wood or deck. With this formula, you will be giving your wooden structures adequate protection against the harmful Ultra Violet rays from the sunlight. MicroShades is a pressure treated wood fence that has the red tone color of cedar.

The color is infused as the wood is being pressure treated so you get the color you want from the very beginning. Pressure washing is almost always a must on older decks, but be sure not to use too much pressure. Certain chemicals, such as the water-repellent CA-C (copper azole type C), also makes the wood suitable for ground contact, even in marine environments.

To infuse these preservatives, the wood is immersed and placed in a pressure chamber. Note that, while priming and painting pressure - treated wood may be easiest with a paint sprayer, opt for a brush (or use both in combination) if the job entails detail work. Breathe Fresh Life Into Your Space With New Floors Using Our New Room Makeover Bundle. Get It Delivered to Your Home.

Recycled plastic lumber. Varathane Offers A Wide Array Of Colors From Traditional To Contemporary.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.